Anyone with an irrational fear of a pending robot uprising may want to look away, because they have just taken one more step towards autonomy. Piaggio Fast Forward (PFF) and Trimble have announced a proof-of-concept collaboration to enable robots and machines to follow humans and other machines in industrial applications.

Many robots are currently controlled by joysticks operated in person or by telepresence from a remote location, but the new prototype eliminates the need for sole control via a joystick. The smart following technology allows humans to lead robots and machines in dynamic environments. “The follow-me technology by PFF provides an intuitive user experience and opens the door to collaborative robots that can augment the human workforce,” said Aviad Almagor, Division Vice President, Trimble’s Emerging Technologies, in a release.

PFF has componetized the smart following technology developed by PFF’s Gita robot into a stand-alone module called PFFtag. PFF and Trimble have integrated this patent-pending PFFtag smart following module prototype onto a Boston Dynamics Spot robot platform controlled by Trimble’s advanced positioning technology.

With the push of a button, a fused sensor array is activated and paired to a leader who navigates the robot or machine through construction or civil engineering spaces. PFFtag enables external partners to leverage its exclusive algorithms and allow their software to communicate with PFF’s software, enabling a human to control the robot via pairing and improving the robot’s ability to sense direction and velocity as it follows the leader. While on a site walk, waypoints can be dropped with the push of a button. Once trained by following, paths can be repeated by the robot autonomously with the ability to avoid obstacles and respond to a changing environment.

No app, tablet, or special training to operate a joystick is needed. Additionally, multiple robots or machines can be “linked” together like ducklings following their mother to create a platooning effect.

Trimble conducted testing using a Spot robot equipped with Trimble laser scanning or Global Navigation System sensors and PFFtag technology at one of its customer’s sites in Colorado over the course of two months as part of the proof-of-concept. In the future, PFF and Trimble envision robots with PFFtag having the ability to assist construction professionals in their daily workflow, carry heavy equipment, improve efficiency, and enhance worker safety.

Related Stories

75 Top Building Products | Apr 22, 2024

Enter today! BD+C's 75 Top Building Products for 2024

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2024 issue of Building Design+Construction.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Sustainability | Nov 1, 2023

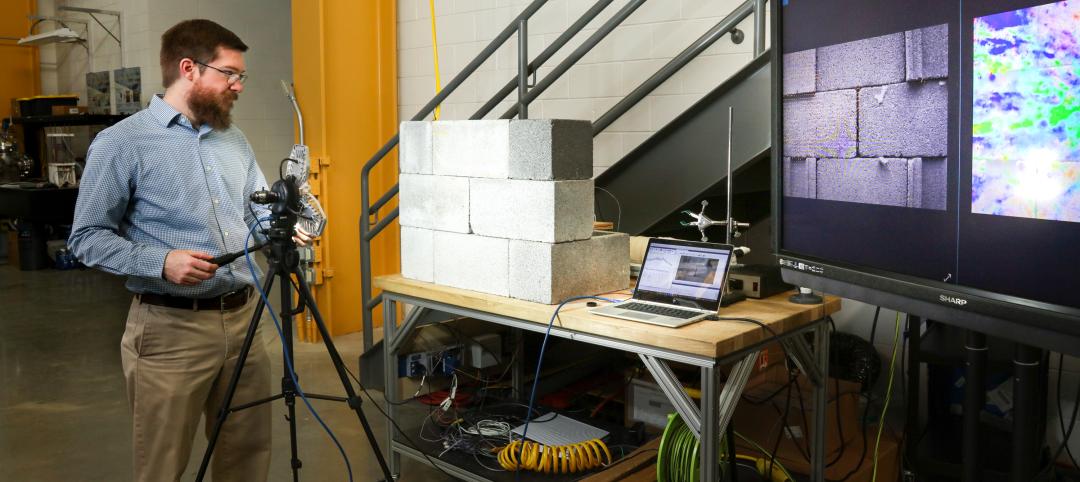

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Resiliency | Aug 7, 2023

Creative ways cities are seeking to beat urban heat gain

As temperatures in many areas hit record highs this summer, cities around the world are turning to creative solutions to cope with the heat. Here are several creative ways cities are seeking to beat urban heat gain.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.