A half-century ago, building codes were simpler.

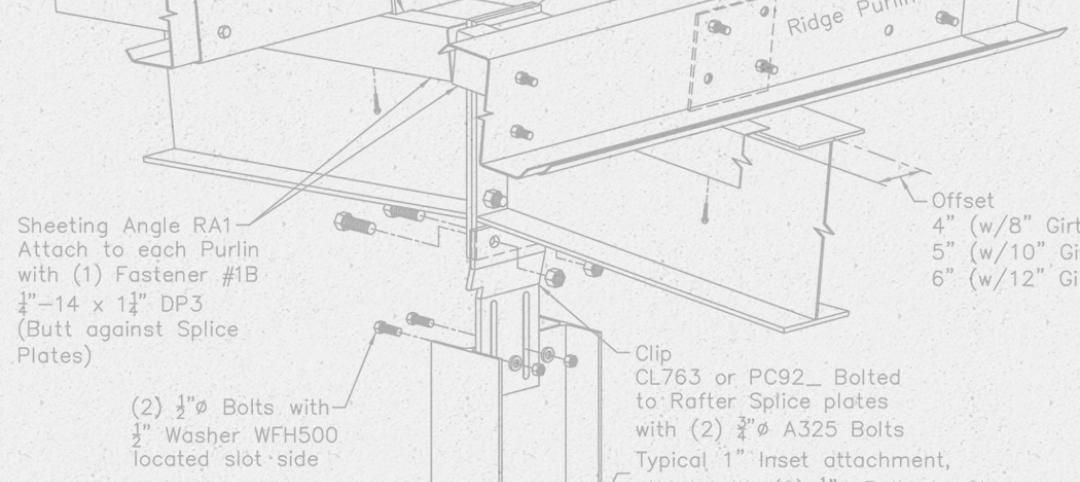

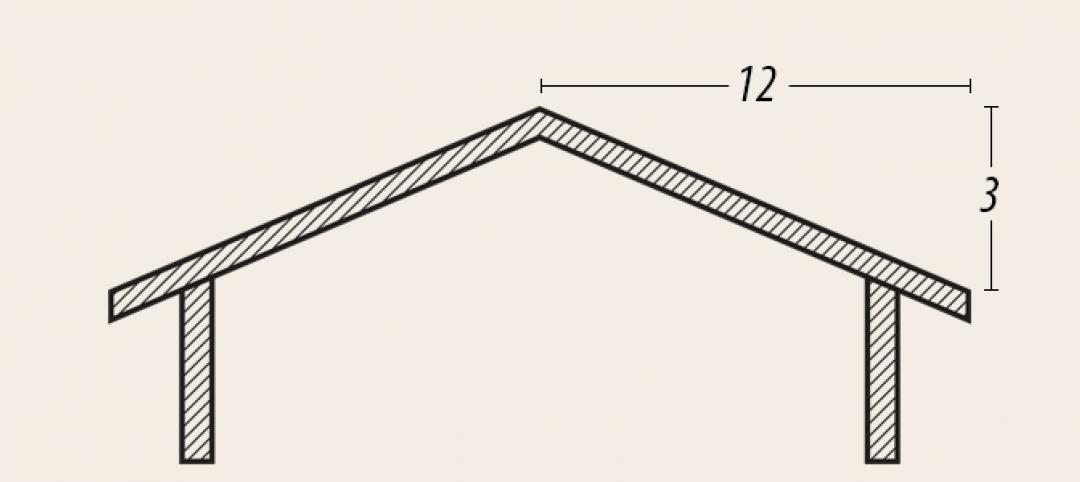

It was an era when most engineers still performed their calculations by hand – literally, using a slide rule. Building materials were looked on as essentially inexhaustible resources, and nobody was worried about the carbon footprint of producing and shipping the materials. So it made sense to err on the side of caution: calculate the maximum loads and build everything to that strength. For example, the snow load capacity of a roof was calculated for the entire roof as a single condition, and every part of the roof had to be capable of supporting the maximum load. This insured that the parts of the roof where the most snow accumulated were able to handle the load. However, the parts on which the least snow accumulated had the same high-load capacity, and those areas might be significantly overbuilt.

Loading conditions that were very broadly defined limited the number of combinations that needed to be calculated. Human-powered engineering that involved calculations done on slide rules was still feasible and affordable.

But over time, codes have evolved to be more specific and nuanced. More detailed analysis of the way structures work has led to subdividing the broad conditions of older codes into narrower and more specific categories. Going back to the snow load example, the International Building Code (IBC) introduced the idea of unbalanced snow loads in 2000, taking into account the fact that wind causes snow to pile up more on one side of a roof than the other. In 2003 and 2006, those provisions were refined even further.

The result is that today’s codes define more efficient, effective structures, but the engineering of them has become vastly more complex. Where there once might have been six combinations of conditions, there are now hundreds.

If engineers had to do all those calculations by hand, the construction industry could grind to a halt. Fortunately, as codes evolved, machined-based computational power – computers – also evolved.

Computer-assisted engineering dates back to the 1960’s, when computers were very large and very expensive, yet relatively primitive in their abilities. All instructions and data came from paper punch cards, involving big decks of hundreds of cards punched on hand-operated, typewriter-like machines that were fed into the computer in a big stack. Each computer might be a series of machines nearly six feet tall, lining most of the walls of a room the size of half a tennis court, yet only have the computing power of today’s cheap digital watches. Nonetheless, it was still much faster than calculating by hand.

Star Buildings recognized the value of this resource very early on, and became a leader in computer-assisted engineering.

Today’s computers are far more powerful and fast; capable of engineering tasks that simply would not have been possible before.

As a result of this parallel evolution of codes and computerized engineering, metal buildings and all building in general are being built with much more efficient use of materials, maintaining and even exceeding the safety of the structures of previous decades.

For more on the safety and longevity of metal building systems, download the whitepaper here.

More from Author

Bryan Arlington | Nov 21, 2016

Ready for earthquakes?

There is a mistaken belief among some people that steel buildings do not do well in earthquakes. The truth is quite the opposite.

Bryan Arlington | Aug 24, 2016

Rolling Sheet Door Considerations

The pros and cons of a rolling sheet door

Bryan Arlington | Aug 19, 2016

Standards. Do You Have Them?

Metal building standard for contractors and erectors.

Bryan Arlington | Apr 24, 2015

Are metal roofs lightning magnets?

According to The Metal Construction Assocition, a metal roof will not make lightning more likely to strike, but it may make a lightning strike less dangerous if it occurs. That’s right, less dangerous, not more.

Bryan Arlington | Mar 31, 2014

Tips for creating a competitive bid using codes and loads

Landing a project feels like winning a prize, sort of like finding that forgotten $20 bill in the pocket of a pair of jeans you haven’t worn in a while. But living on the “chance” of winning a job isn’t a great way to pay your electric bill. So, how do you swing the chances in your favor?

Bryan Arlington | Mar 19, 2014

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.

Bryan Arlington | Jan 6, 2014

What is value engineering?

If you had to define value engineering in a single word, you might boil it down to "efficiency." That would be one word, but it wouldn’t be accurate.