Keys to understanding this common construction practice—from field-cutting techniques and proper tools to tips for preserving metal roof and wall panel appearance and longevity.

Field cutting of metal panels, particularly at framed openings, is an acceptable alternative to cutting in a manufacturing facility. Most metal panel manufacturers, in fact, will allow (and expect) installers to cut metal roofing and wall panels on-site, but in order for the panels to be protected from damage and ensure the longevity that metal panels are known for, there are certain do’s and don’ts when it comes to recommended cutting methods, tools, and even the location where the cutting is done.

Overview of Field Cutting Metal Panels to Maintain Longevity

Methods, tools and even the location of where the cutting is taking place can all affect the performance and appearance of the metal panels being cut on-site, so it is important to follow certain protocols and guidelines. Best practices include:

-

Methods: When cutting metal panels on-site or in the field, protecting the cut edges is critical to maintaining the integrity of the panels. Mimicking how cutting is done at the manufacturing facility will yield the best results and will provide a roadmap to the quality you should be aiming for.

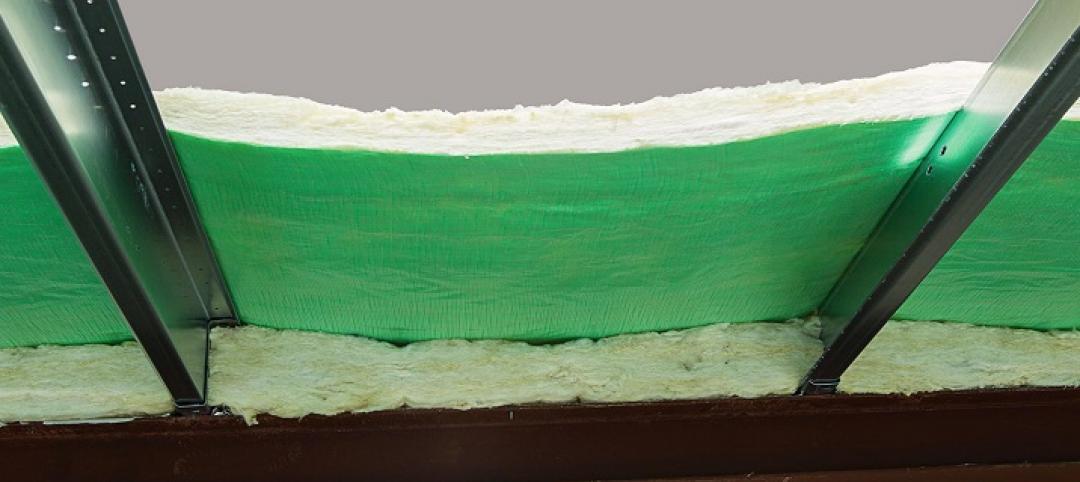

The first thing to note is that metal roof and wall panels are usually fabricated from Galvalume®-coated steel coil because of its longevity and protective properties. Manufacturing facilities employ tools and methods to cut the coated metal coil, which helps protect the cut edge from deterioration (ex.: rust and corrosion). Also, during fabrication, the coated metal is cut to length either by shearing while flat before entering the roll former, or by the use of a profile shear as the panels exit the roll former. These methods serve to “wipe” the Galvalume coating across the cut edge of the metal panels, providing superior cut-edge protection from corrosion.

If field cutting is needed once the panels arrive on-site, it is important to similarly protect the edge of the steel from corrosion by following recommended strategies and protocols. - Location: It is best to cut the metal panel down on the ground, rather on the roof or over other metal panels. Why? Anytime metal is cut, fine particles of steel debris (called swarf) are produced and will fall from the cut area. If these particles fall on the roof, permanent staining can occur. Additionally, if significant accumulation occurs in one spot, it could rust completely through the metal roof panel, causing long-term problems. Ideally, then, you’d want to cut the panels in such a way that the swarf can be captured and properly disposed of.

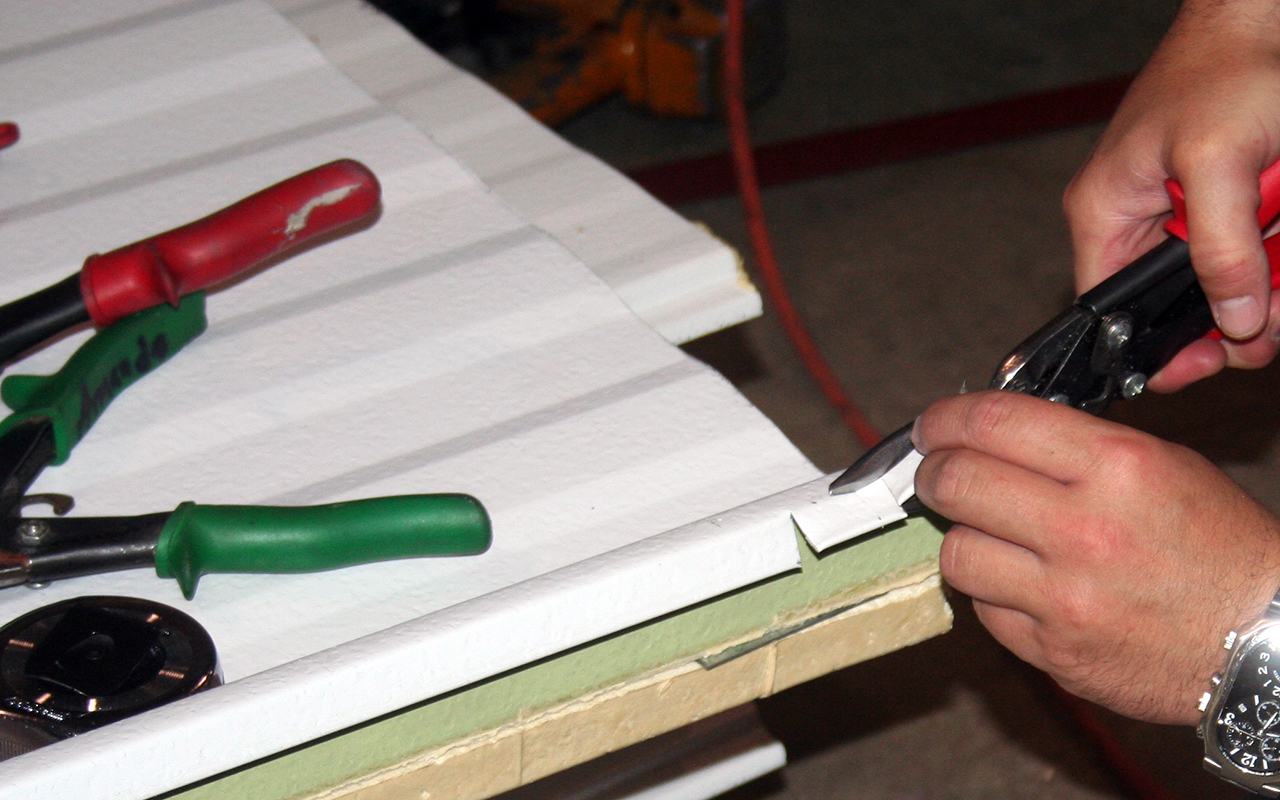

- Tools: When field cutting is required, the metal roof or wall panels should be cut with a tool that prevents edge rusting, such as nibblers, snips or shears. Conversely, saws, abrasive blades, grinders or torches should never be used as they are likely to leave irregular or rough edges that are no longer coated or finished, thereby causing rust and corrosion. Additionally, because a skill saw blade or other abrasive blade will throw considerable amounts of swarf into the air and down onto any panels below (see recommendations about cutting location above), the swarf, which will be hot, will embed into the panel coating, causing the area to rust.

Common Tools for Cutting Metal Panels on the Jobsite

The old saying that you only get out what you put in holds true for metal panel cutting. Using the right tools (in the right way) can ensure good results, while the wrong tools can result in an array of unfortunate and long-lasting problems, such as rust and rust stains, voiding of warranties, and compromised building service life.Among the features of good tool choices for field-cutting metal panels are those that will wipe the Galvalume coating, are cool, and will protect edges. Recommended tools include the following:

- Aviation snips—both red and green. These tools are often used for small cuts on metal panels, such as around pipe penetrations. Among the benefits is that aviation snips will wipe the Galvalume® coating in a way similar to factory shears. Aviation snips have a double pivot, are spring-loaded, and have a safety lock. Red snips cut left; green snips cut right.

- Electric shears are useful for providing clean, precise and straight cuts. This tool is typically used when making lengthier cuts along the steel (ex.: cutting a wall panel at a corner or at a door opening). Electric shears will take a ¼” strip of metal out of the panel during the cutting process. This process tends to leave both sides of the panel smooth and flat along the cut. Electric shears will also wipe the Galvalume® coating over the cut edges to offer protection.

- Mechanical shears do not take any metal out of the panel and will leave a slightly wavy edge. An add-on tool that fits onto a battery-operated impact or screw gun,mechanical shears are a good option for bevel cutting standing-seam panels at hips and valleys. Like the other tools mentioned above, mechanical shear swipe the Galvalume® coating and protect the edges.

- Nibblers are an excellent choice when the job calls for cutting across corrugations in metal wall panels to create openings for windows, doors and similar additions. It is not uncommon to see product descriptions noting that this tool cuts through metal, “like butter.”Typically, nibblers cost several hundred dollars, but are worth the cost if you need to cut a lot of corrugated metal panels. Nibblers have a punch and die, which tend to wipe the Galvalume® across the cut edge as it punches out small, half-moon shaped pieces of the metal panel. One caveat is to take proper precautions with these metal pieces, which will invariably fall away from the cut. They must be contained so that no one walks on them as these small pieces can become embedded in the soles of shoes and create scratches in roof panels.

- Skill Saws are versatile tools that enable cutting to be done either across or parallel to corrugations, whether straight or at an angle. Choose a saw blade that cuts cool. Otherwise, the Galvalume® coating can melt along the cut edge and become ineffective. This cool-cutting blade will leave a desirable, smooth edge. Additionally, do not use an abrasive blade, which will generate heat and damage the coating (see more below).

STOP! Do not use these tools.

Equally important as using the right tools is NOT using the wrong tools. When cutting metal panels on-site, never use the following tools—torches, reciprocating saws, hacksaws and grinders—as they will melt the Galvalume® coating, causing edge rust just like an abrasive blade would.

In conclusion, using the right tools and following the recommendations provided by the metal panel manufacturer when cutting metal in the field will help ensure that the panels are protected from damage, while using the wrong tools can result in rust, rust stains, corrosion, and the voiding of warranties. To find out more about the best practices and recommendations for on-site cutting and installation of metal panels contact your local Star Building Systems representative.

More from Author

Star Building Systems | Oct 13, 2020

Wakarusa Township fire station meets innovation

Kuehler worked in partnership with Lawrence, Kansas-based architectural firm Hernly Associates and together, they created a vision for the new, nearly 14,500-square-foot station.

Star Building Systems | Sep 22, 2020

Applying conventional construction to custom metal buildings

Star Building Systems eliminates a lot of the complexity and allows us to make enhancements with other components to add interest.

Star Building Systems | Sep 10, 2020

David's Catfish House

The building features a wrap-around wood-framed porch, that historically, has the look and feel of what people would consider a catfish house is supposed to look like.

Star Building Systems | Sep 2, 2020

A new look at value engineering

Allowing your expert material supplier to direct you as to how to get as close to that optimal price point as possible is value engineering—emphasis on “value.”