Since the 1950s, architects have explored design possibilities with wire mesh and perforated metal panels in buildings. Until then, the technology had primarily been used for mundane construction applications like fences, concrete reinforcement, and lockers.

One of the earliest architectural installations of woven wire mesh—the elevator interiors in the Mies van der Rohe-designed Seagram Building in New York City—still adorns the spaces today.

Both metal mesh and perforated panels have become increasingly popular design solutions due to the sleek, modern aesthetic they afford and the multiple functions they serve. Installations commonly serve as one part art piece, one part security and safety barrier, protecting against everything from break-ins to falls to bomb blasts.

ALSO SEE: 6 ways to use metal screens and mesh for best effect

Of course, the technology has advanced over the years and installations have become much more sophisticated. Here are five recent projects that represent that latest in woven wire and perforated metal panel systems.

1. ‘Folding’ façade turns LAPD’s eyesore into architectural showcase

Woven mesh and perforated metal panels have long been a popular solution for scaling down bulky concrete parking structures while simultaneously meeting security and safety requirements. They are a relatively inexpensive approach that can have a major impact on the viability of real estate developments—thoughtful parking garage design is often the linchpin of successful projects.

But while most metal-clad parking structures are quite mundane, the LAPD Motor Transport Division’s 800-car parking structure in downtown Los Angeles is anything but. Cladding four of the five stories is a series of vertically oriented woven wire mesh panels that cleverly fold in, out, and around cantilevered walkways that serve as the primary access to the parking levels. The 34 eight-foot-wide mesh panels are fashioned to a steel pipe frame that is attached to the concrete structure with horizontal members of varying length, creating the angular, folding aesthetic.

The panels are painted in a pattern of leaf-like forms with two tones of green (to represent the “greening” of L.A.) that provide a glowing effect at night when sprayed with light. Instead of getting an eyesore, the community gets a safe, well-lit parking structure that is a beacon of great design.

LAPD Motor Transport Division

and Main Street Parking

Los Angeles

Clients: City of Los Angeles, Bureau of Engineering for Los Angeles Police Department

Architect: John Friedman Alice Kimm Architects

Engineer (structural, MEP): TMAD Taylor and Gaines

General contractor: S.J. Amoroso

Metal panel system manufacturer: W.S. Tyler

2. LEDs shine at Translational Research Institute

Set in sunny central Florida, the 37,000-sf Translational Research Institute for Diabetes and Metabolism is veiled in a series of woven stainless steel mesh panels to help reduce solar heat gain and minimize glare in the workspaces while still permitting daylight and views. Flad Architects, Madison, Wis., specified a cube-shaped weave for the street-facing elevation that is highly transparent, with 74% open area, yet offers sufficient shading to meet the design requirements.

The installation is among the growing number of metal mesh projects to incorporate LED lighting for added visual effect and functionality. Advancements in both LED technology and metal mesh systems have led to increasingly sophisticated installations in recent years. For instance, some mesh system manufacturers offer the ability to display graphics and images, or even stream live video, using integrated LEDs.

On this project, yellow LEDs were used to create a crisscrossing effect that is meant to reflect the advancements in research and technology occurring within the facility. As day turns to night, the building’s mesh-clad façade disappears almost completely, giving focus to the LED artwork and illuminated curtain wall behind the screen.

Translational Research Institute for Diabetes and Metabolism

Orlando, Fla.

Clients: Florida Hospital, Sanford-Burnham Medical Research Institute

Architect: Flad Architects

General contractor: Brasfield & Gorrie

Metal panel system manufacturer: Cambridge Architectural

3. Operable metal skin creates ever-changing façade in West Hollywood

Homeowners in this 12-unit, LEED Platinum condo development in West Hollywood get the ultimate in privacy, security, and daylight control thanks to an unusual double-wall façade scheme. The outer skin, which wraps three of the four floors, is made of 1/8-inch-thick perforated aluminum panels fastened to an aluminum frame. The frame incorporates bifold doors at each balcony, which allow the residents to open and close the metal screen as they please. The building’s operable aluminum skin also reduces ambient noise in the urban setting and encourages occupants to utilize natural ventilation in lieu of the mechanical systems.

The architect’s design intent was to create a façade in a constant state of change, much like that of the inhabitants of the building. The result is a structure that, while modern in appearance, has organic qualities. The architect describes it as “a live canvas to be painted upon daily or more often.”

The aluminum substructure was fabricated in a factory and prepared for ease of installation without the need for field fabrication. The anchoring brackets were engineered to allow for expansion and seismic movement, meeting seismic code requirements for the region.

The Lofts at Cherokee Studios

West Hollywood, Calif.

Client: REthink Development

Architect: Brooks + Scarpa Architects

Contractor: JT Builders

Metal panel system manufacturer: C.R. Laurence

4. Bowling Green turns drab chiller plant into stainless steel showpiece

When officials at Bowling Green State University learned that a chiller plant expansion was necessary to meet the cooling loads for campus buildings, they could have easily built a drab, utilitarian building like the thousands of power facilities that dot college and university campuses across the country. Instead, the university’s Office of Design and Construction worked with design architect Bostwick Design Partnership, Cleveland, to develop a scheme that not only met the engineering requirements but further created a showpiece for the campus.

Tucked between the School of Art and Conklin Hall, the plant takes the shape of a massive fin or wedge, wrapped in a shimmering veil of stainless steel. More than 10,000 sf of ¾-inch-thick perforated screen panels were used to clad the structure, which features a corbelled brick base to conceal the bulk of the chiller plant systems.

The metal panels are situated vertically, creating almost a drape effect, and have a staggered perforation pattern and ribbed styling for minimal transparency. The screens provide about 30% open space, which affords views of the equipment from certain vantage points.

The design team paid close attention to the orientation and placement of the structure to work within the campus’s master plan and enhance its dual role as chiller plant and art piece.

Bowling Green State University Chiller Plant

Bowling Green, Ohio

Client: Bowling Green State University

Architect: Bostwick Design Partnership

Contractor: Industrial Power Systems

Metal panel system manufacturer: Centria

5. Mesh wall doubles as massive marquee for AmericanAirlines Arena

Four times the size of an average billboard, the 42-foot-wide, 80-foot-tall marquee above the main entrance to Miami’s AmericanAirlines Arena appears to be a typical large-screen TV; it’s actually a first-of-its-kind, large-scale LED mesh media wall in the U.S. The monitor is made from 3,400 sf of woven stainless steel mesh fabric with interwoven LED profiles that provide the pixels for displaying high-resolution digital images and video.

The key advantage of integrating the large-scale media display with mesh screen panels is transparency—when the LEDs are turned off, the monitor simply disappears, revealing the architecture behind. The mesh screen is ¾-inch-thick yet 70% transparent, blending in with the architecture of the arena. Additional benefits: it uses a about a sixth of the electricity required to power conventional LED boards; requires minimal maintenance; and can stand up to Florida’s harsh weather conditions, including hurricane-force winds up to 146 mph.

AmericanAirlines Arena

Miami

Clients: Miami-Dade County (owner),

Basketball Properties Ltd. (operator)

Mesh system designer/installer: GKD-USA

Mesh system specifier/architect: A2aMEDIA

BONUS: Aluminum mural ‘lights up’ Valparaiso University

In planning the new 51,500-sf College of Arts & Science Building at Valparaiso (Ind.) University, school officials desired a design element that celebrated the rich cultural diversity on campus. The university’s 4,060 students hail from more than three-dozen countries, representing 30 languages.

Design architect EHDD, San Francisco, dreamed up a novel scheme that involved “printing” the university’s Latin motto—“In luce tua videmus lucem,” which translates to “In thy light, we see light”—in all 30 languages on a massive metal plate mounted over the building’s main entrance. EHDD designer Joseph Schollmeyer, LEED AP, says the “tapestry of words” is an amalgamation of translations for the word “light.” The nine languages taught in the building are larger, and the motto itself is situated at the center of the screen.

The design team worked with Doralco Architectural Metal Solutions to create the mural by cutting the complex pattern into six half-inch-thick aluminum plates using a waterjet cutter. The plates were welded together and painted gray in the factory, then shipped to the job site. The resulting screen spans 30 feet in width and the full height of the window wall above the entrance. At night, the interior lights in the building’s faculty commons room create a glowing silhouette effect.

“The screen serves as a marquee, giving a unique identity to the otherwise humble piece of architecture,” says Schollmeyer.

Related Stories

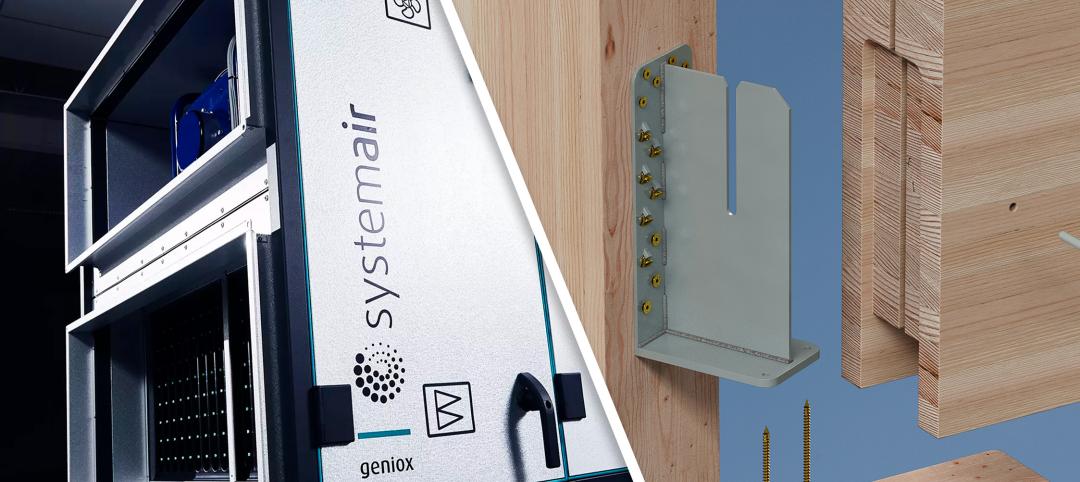

75 Top Building Products | Dec 13, 2023

75 top building products for 2023

From a bladeless rooftop wind energy system, to a troffer light fixture with built-in continuous visible light disinfection, innovation is plentiful in Building Design+Construction's annual 75 Top Products report.

Sustainability | Nov 1, 2023

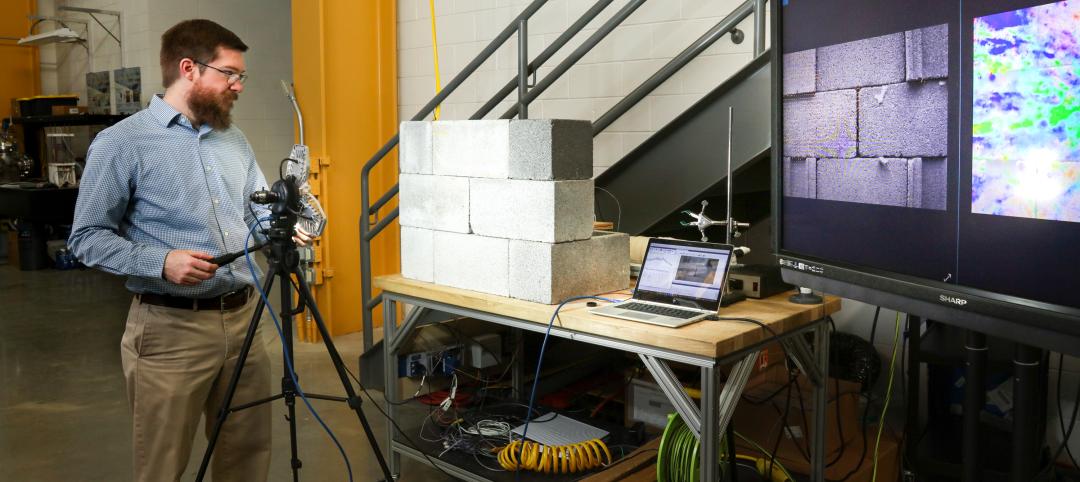

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Products and Materials | Oct 31, 2023

Top building products for October 2023

BD+C Editors break down 15 of the top building products this month, from structural round timber to air handling units.

75 Top Building Products | Aug 7, 2023

Enter today! BD+C's 75 Top Building Products for 2023

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2023 issue of Building Design+Construction.

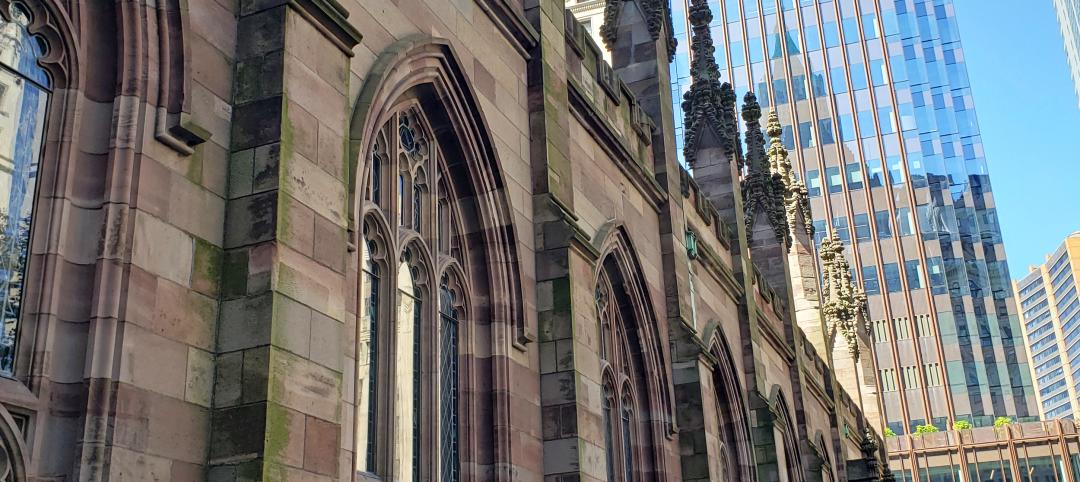

Cladding and Facade Systems | Jun 5, 2023

27 important questions about façade leakage

Walter P Moore’s Darek Brandt discusses the key questions building owners and property managers should be asking to determine the health of their building's façade.

Sponsored | Building Enclosure Systems | May 16, 2023

4 steps to a better building enclosure

Dividing the outside environment from the interior, the building enclosure is one of the most important parts of the structure. The enclosure not only defines the building’s aesthetic, but also protects occupants from the elements and facilitates a comfortable, controlled climate. With dozens of components comprising the exterior assemblies, from foundation to cladding to roof, figuring out which concerns to address first can be daunting.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Cladding and Facade Systems | Apr 5, 2023

Façade innovation: University of Stuttgart tests a ‘saturated building skin’ for lessening heat islands

HydroSKIN is a façade made with textiles that stores rainwater and uses it later to cool hot building exteriors. The façade innovation consists of an external, multilayered 3D textile that acts as a water collector and evaporator.

Mechanical Systems | Jan 17, 2023

Why the auto industry is key to designing healthier, more comfortable buildings

Peter Alspach of NBBJ shares how workplaces can benefit from a few automotive industry techniques.