When The Shed, a $435 million arts, education, and entertainment center in New York City, had its grand opening in the spring of 2019, it attracted attention for its 115-foot-tall moveable canopy that, when fully opened, adds 17,000 sf of light-, sound-, and temperature-controlled multipurpose space; and when fully retracted into the 200,000-sf building uncovers an open-air public plaza.

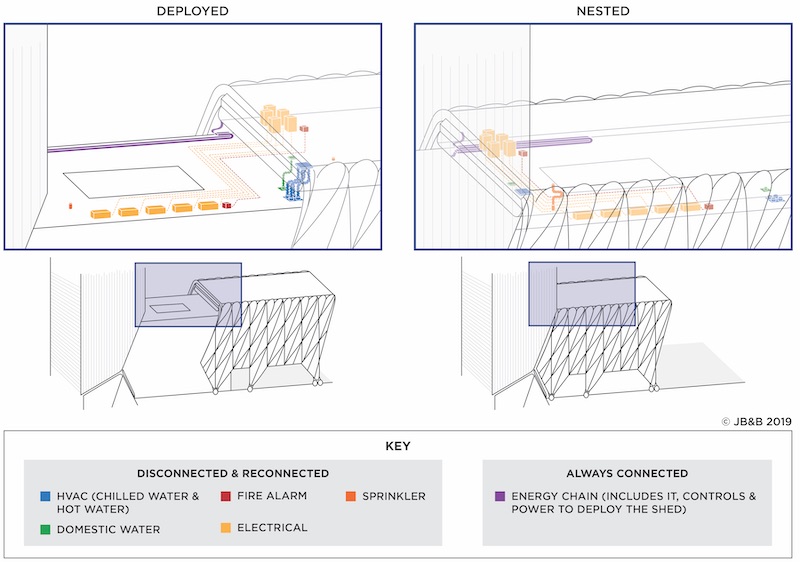

What’s less appreciated, perhaps, by The Shed’s visitors, students, and performers is its electrical interconnection system that powers the building’s nested and deployed positions, and that must be disconnected and connected every time the canopy opens and closes.

“I don’t know of any other moveable building in the world that’s like this. We built it like a Swiss watch,” says Mark Torre, PE, LEED AP, Managing Partner with Jaros, Baum and Bolles (JB&B), the project’s MEP and fire protection consultant.

As originally designed by Diller, Scofidio + Renfro in collaboration with Rockwell Group, The Shed had two moveable features, each of which would have needed to be heated and cooled. (Torre says that design was scotched as being too complex and costly.)

The project team also thought it would have more space below The Shed for its mechanical room, but that didn’t work out, either. At one point, there was some thought given to running air conditioning ducts through manholes, but that idea was rejected because the system would have cooled only about 15% of the performance space.

So the 850,000 lbs of mechanicals—including the building maintenance unit, HVAC, plumbing, conduit, and other equipment—are above the canopy’s lighting rig. Scott Lomax, Senior Principal with Thornton Tomasetti, the project’s structural engineer, says that based on The Shed’s current programming needs, the project team predicted that the 6.1 million-lb canopy will retract about once per month through the life of the building.

See Also: The Shed arts center includes a massive, telescoping outer shell

To facilitate that movement, JB&B created attachment points (both nested and not), which Torre says required precise installation of systems that would be disconnected and reconnected as needed. These systems include normal utility power, legally required standby power, emergency power, fire alarm power and communications, chilled and hot water supply and return, domestic water makeup (which addresses evaporation and maintenance issues), and sprinkler service for the mechanical deck above the event space. The connect/disconnect are performed manually and take about six hours to complete, says Torre. The Shed services that remain connected through the “power chain” include the building management system’s communications and power, information technology, and power for the canopy’s motors and kinetics control system.

Torre notes that nearly all of The Shed’s mechanical systems (for the moveable portions) required variances. These included the energy chain power (for permanent flexible power wiring) as well as the methods for connecting and disconnecting the moveable Shed.

Related Stories

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Sustainability | Nov 1, 2023

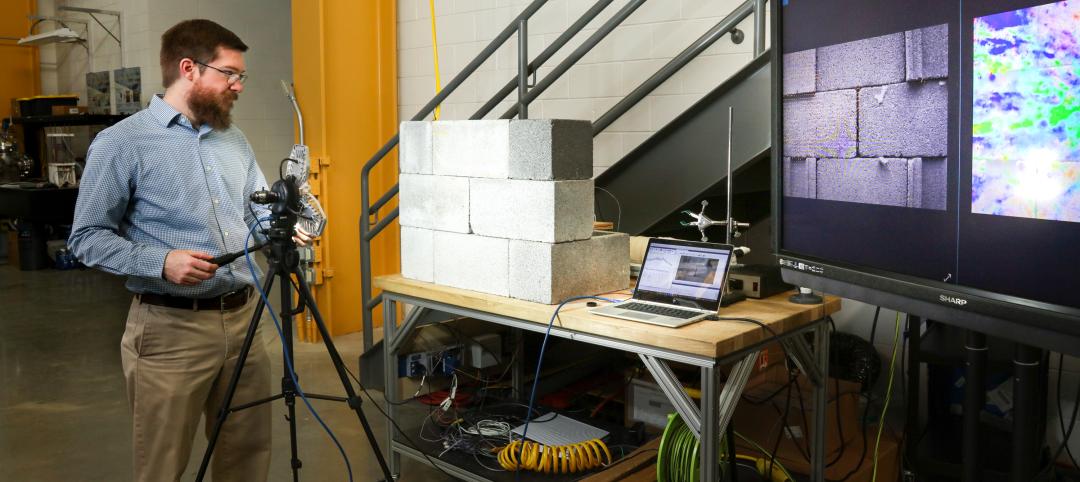

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

75 Top Building Products | Aug 7, 2023

Enter today! BD+C's 75 Top Building Products for 2023

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2023 issue of Building Design+Construction.

Resiliency | Aug 7, 2023

Creative ways cities are seeking to beat urban heat gain

As temperatures in many areas hit record highs this summer, cities around the world are turning to creative solutions to cope with the heat. Here are several creative ways cities are seeking to beat urban heat gain.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.