As technologies evolve, they typically tend to grow smaller and more convenient. The first computer occupied about 1,800 sf and weighed almost 50 tons. Now they can be carried with us everywhere. The first cell phone weighed almost two and a half pounds, not the paltry 50 to 100 grams a basic smartphone weighs today.

As a piece of technology becomes smaller, lighter, and more convenient, the applications for that device increase. Like computers before them, 3D laser scanners, a technology that has become a prevalent tool among AEC professionals, have recently crossed into the territory of handhelds.

The FARO Freestyle 3D handheld laser scanner is one such technology that has been released in the past few years. The device comes in a kit that includes the scanner, charging cables, associated USB devices, a Microsoft Pro Surface tablet, and a calibration plate.

The carbon-fiber scanner, which looks like it would fit right in with the Mystery Science Theater 3000 crew, has 3D point accuracy of ≤1.5mm (the Freestyle 3DX provides 3D point accuracy of ≤1.0mm) and an indoor scanning volume of up to 8m³. The 3D scan data can be imported into commonly used software for architecture, engineering, and construction applications.

The compact, handheld nature of the Freestyle 3D allows AEC professionals to measure and scan in tight, hard-to-reach areas that traditional scanners have been unable to access in the past.

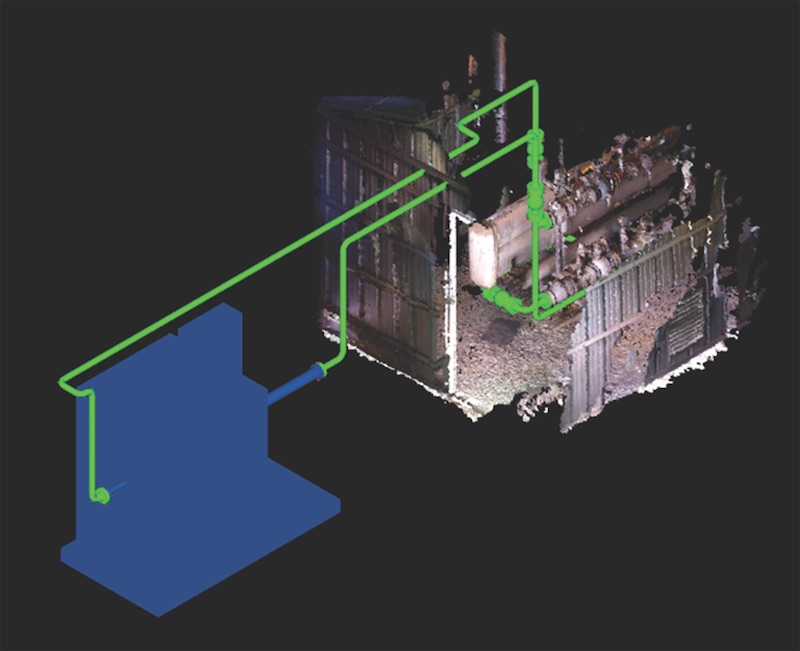

A handheld scanner was used to scan an existing fuel gas preheater to create this image, which shows how it would connect to a planned new fuel gas preheater. Courtesy SSOE Group.

A handheld scanner was used to scan an existing fuel gas preheater to create this image, which shows how it would connect to a planned new fuel gas preheater. Courtesy SSOE Group.

Handhelds in the Field

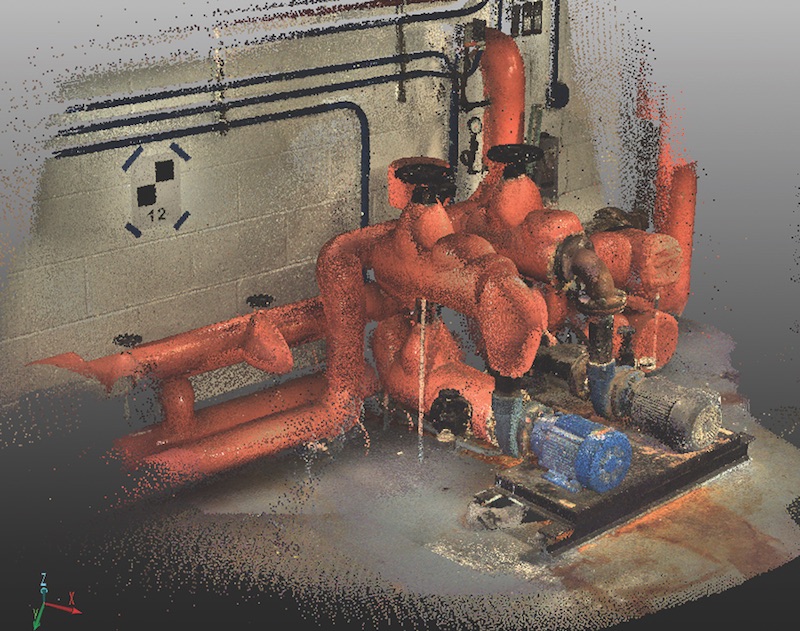

Actus3D, a New York-based 3D laser scanning and consulting firm, recently used the Freestyle 3D scanner to document One Liberty Plaza in Manhattan. The primary task of the project was to create a BIM model from 3D laser scans of the building’s interior spaces, including the mechanical rooms.

The handheld scanner allowed the architects to capture compressors, elevator machines, and pipe assemblies in significant detail, and gain accurate measurements that would have otherwise taken much longer. The Freestyle scans were then combined with scans from a FARO X330 scanner to provide a more complete point cloud dataset that was free of the usual voids that occur using standard static scanning.

“The freestyle scanner has also been beneficial in scanning on-site steel connections that require documentation,” says John Smits, President, Actus3D. “Rather than taking multiple measurements and sketches on site, the connection detail can be quickly scanned using reference points, then processed and brought into CAD to produce accurate layouts of the bolt locations and bent plates.”

Architects and engineers with SSOE Group believe one of the biggest benefits handheld scanners provide is the ability to show clients results immediately after taking a scan.

In one particular project SSOE worked on, a handheld scanner was used to scan a piece of equipment quickly and incorporate the design of new piping tie-ins to the equipment. One week after the scan, SSOE was able to show the results to the client with a workable model that gave an accurate representation of their facility equipment.

“As a result of using a handheld 3D scanner, our team was able to drastically change the approach of the design on the next phase of the project, which resulted in a 7% efficiency gain in our productivity,” says Jason Christen, PMP, Senior Project Manager with SSOE Group. “This small handheld scanner was the springboard that resulted in $1 million in cost savings for our client.”

Since jobs that involve capturing field conditions for small equipment, piping, and electrical upgrades tend to have small budgets, the use of traditional 3D laser scanners can be too costly at times. This is where handhelds excel. They can be carried with engineers already visiting a site as part of the due diligence process.

On one SSOE project, an engineer went to the field and spent three hours using a handheld scanner to capture the rip and replace of a piping skid. This project was originally budgeted for 80 hours to document and create a 2D plan.

“This particular job was a time and materials budget, and we were able to save 100 hours out of the original 400 hours to execute the job and a 25% savings on our fee for the client,” says Mark LaBell, Senior Virtual Design and Construction Technical Leader with SSOE Group.

A completed scan, done with a FARO Freestyle 3D, of an assemblage of pipes and machines at One Liberty Plaza in Manhattan. The handheld scanner was used in tandem with the FARO X330 scanner to provide a more complete point cloud dataset while eliminating the usual voids left behind by static scanning. Courtesy: Actus3D.

A completed scan, done with a FARO Freestyle 3D, of an assemblage of pipes and machines at One Liberty Plaza in Manhattan. The handheld scanner was used in tandem with the FARO X330 scanner to provide a more complete point cloud dataset while eliminating the usual voids left behind by static scanning. Courtesy: Actus3D.

The Middle Ground

While not a handheld, the Leica Geosystems BLK360 represents a middle ground between traditional laser scanners and handheld systems like the Freestyle 3D. It is compact, weighing just 2.2 lbs., and can be easily carried by an AEC professional during a routine site visit.

However, where the FARO Freestyle 3D requires a user to operate and position the scanner, the BLK360 is placed on a level surface and captures 360-degree HDR spherical imagery with the push of a button—accurately scanning up to 60 meters in minutes with a 360,000-point-per-second laser scan.

According to Leica, the BLK360 has 3D point accuracies of 6mm at 10 meters and approximately 8mm at 20 meters. Both the BLK360 and the Freestyle 3D create a point cloud where multiple scans can be combined to create a more complete image.

As the BLK360 captures data, it begins to transfer it to the accompanying tablet, which allows the user to see the image build up as the scans are captured. The average time for total capture, which includes images and scan, is three minutes.

Related Stories

BIM and Information Technology | Mar 11, 2024

BIM at LOD400: Why Level of Development 400 matters for design and virtual construction

As construction projects grow more complex, producing a building information model at Level of Development 400 (LOD400) can accelerate schedules, increase savings, and reduce risk, writes Stephen E. Blumenbaum, PE, SE, Walter P Moore's Director of Construction Engineering.

AEC Tech | Mar 9, 2024

9 steps for implementing digital transformation in your AEC business

Regardless of a businesses size and type, digital solutions like workflow automation software, AI-based analytics, and integrations can significantly enhance efficiency, productivity, and competitiveness.

AEC Tech | Feb 28, 2024

How to harness LIDAR and BIM technology for precise building data, equipment needs

By following the Scan to Point Cloud + Point Cloud to BIM process, organizations can leverage the power of LIDAR and BIM technology at the same time. This optimizes the documentation of existing building conditions, functions, and equipment needs as a current condition and as a starting point for future physical plant expansion projects.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

AEC Tech | Jan 24, 2024

4 ways AEC firms can benefit from digital transformation

While going digital might seem like a playground solely for industry giants, the truth is that any company can benefit from the power of technology.

AEC Tech | Jan 8, 2024

What's driving the surge of digital transformation in AEC today?

For centuries, the AEC industry has clung to traditional methods and legacy processes—seated patterns that have bred resistance to change. This has made the adoption of new technologies a slow and hesitant process.

Digital Twin | Jul 31, 2023

Creating the foundation for a Digital Twin

Aligning the BIM model with the owner’s asset management system is the crucial first step in creating a Digital Twin. By following these guidelines, organizations can harness the power of Digital Twins to optimize facility management, maintenance planning, and decision-making throughout the building’s lifecycle.

Digital Twin | Jul 17, 2023

Unlocking the power of digital twins: Maximizing success with OKRs

To effectively capitalize on digital twin technology, owners can align their efforts using objectives and key results (OKRs).

Office Buildings | Jun 5, 2023

Office design in the era of Gen Z, AI, and the metaverse

HOK workplace and interior design experts Kay Sargent and Tom Polucci share how the hybrid office is evolving in the era of artificial intelligence, Gen Z, and the metaverse.

AEC Tech | May 9, 2023

4 insights on building product manufacturers getting ‘smart’

Overall, half of building product manufacturers plan to invest in one or more areas of technology in the next three years.