The exoskeleton is a popular science fiction trope: “Aliens,” “District 9,” and “Edge of Tomorrow” all prominently feature the mechanical suits. And as with many sci-fi inventions before it—holograms, 3D printing, self-adjusting shoelaces—exoskeletons are making the jump from the silver screen to the real world.

SuitX industrial exoskeletons reduce the risk of injuries to the wearer without the use of batteries, actuators, or computers. Available in backX, legX, and shoulderX, the modular devices can be combined to form a full-body exoskeleton, called MAX.

BackX can be put on and taken off in 30 seconds and is designed to integrate with standard safety harnesses and tool belts. The module reduces the forces and torques on a wearer’s lower back region (L5/S1 disc) by an average of 60% while stooping, lifting objects, bending, or reaching. It comes in two models. Model S is compatible with legX, weighs 4.9 lbs, and is worn with an exoskeleton harness that weighs 2.5 lbs. Model AC is compatible with legX and shoulderX and weighs 7.5 pounds. It is worn with the same 2.5-lb harness. The Model S frame keeps the rear belt open and accessible for reaching tools, while the Model AC frame is load-bearing and transfers the weight of attached loads directly to the hips or the ground if legX is attached.

See Also: IAQ monitoring for all

LegX allows the wearer to squat repeatedly or for prolonged periods of time by reducing the knee joint and quadriceps muscle forces. The system can distinguish between walking, ascending/descending stairs, and squatting to provide support only when it is needed. A locking mode allows the module to be used like a chair. LegX is offered with a custom work boot to maximize comfort. LegX weighs 13.7 lbs, but is not borne by the user.

ShoulderX reduces gravity induced forces at the shoulder complex, enabling the wearer to perform chest-to-ceiling-level tasks for longer durations and with less effort. The module balances the combined weight of the wearer’s arm and the tool he is holding throughout the body’s range of motion and can be quickly tuned for different levels of support. The support force gradually increases as the user lifts his arms. ShoulderX weighs 9.4 lbs with one arm attached, 11.7 lbs with two arms attached.

When all three modules are combined, the system reduces the muscle force required to complete tasks by as much as 60%, says the maker.

BackX and shoulderX cost $4,000; legX is $6,000.

Related Stories

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Sustainability | Nov 1, 2023

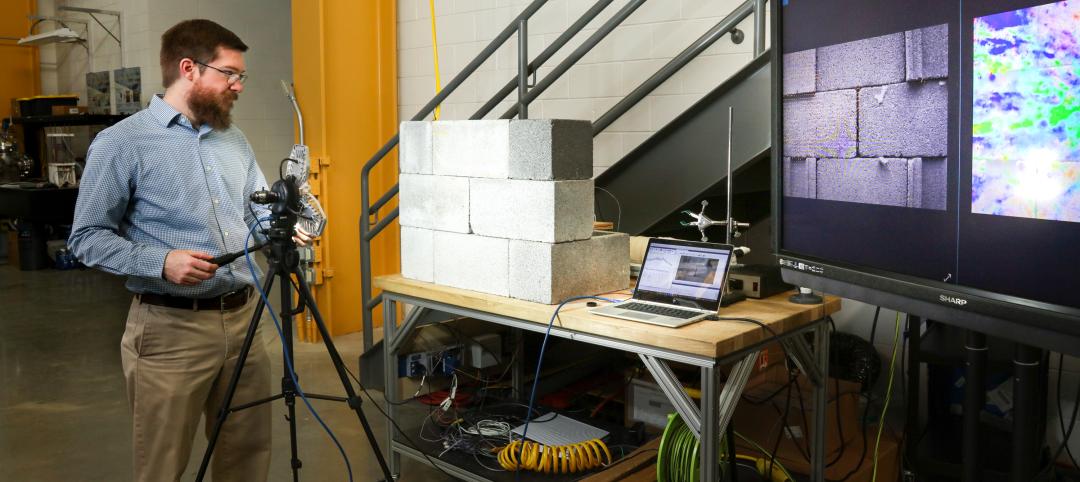

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

75 Top Building Products | Aug 7, 2023

Enter today! BD+C's 75 Top Building Products for 2023

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2023 issue of Building Design+Construction.

Resiliency | Aug 7, 2023

Creative ways cities are seeking to beat urban heat gain

As temperatures in many areas hit record highs this summer, cities around the world are turning to creative solutions to cope with the heat. Here are several creative ways cities are seeking to beat urban heat gain.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.