Project: Public Safety Facility in the East Coast

Architect: Skidmore Owings & Merrill

Glazing Contractor: W&W, LLC

Blast Consultant: Weidlinger Associates

Products: Fire Resistive/Blast Rated System with SuperLite II-XL 120 in GPX Blast Framing and Fire Resistive/Ballistic Rated System with SuperLite II-XL 120 in GPX Ballistic Framing.

A building’s design is very much influenced by the function it performs and the perceived threats that it may face – whether it’s from natural disasters, accidents or terrorist attacks – with the latter being a foremost concern for federal courthouses, embassies, government facilities and other high profile buildings. For these types of facilities, building materials are chosen based on their ability to mitigate or minimize the injuries and fatalities to occupants during an attack. Because of these security concerns, trade-offs have been made when it comes to daylighting, energy efficiency and aesthetics to name a few. The good news is that today, high-performance security glazing make-ups are available in the market place to meet the level of protection needed while continuing to provide natural light and a feeling of openness. These specialized systems can also blend with the surroundings seamlessly to enhance the building’s overall design.

The 1995 bombing of the A.P. Murrah Federal Building in Oklahoma City revealed the devastating effects of high velocity glass fragments on people in the building or those in the vicinity when a blast occurs. This prompted the General Services Administration (GSA) to establish a blast criteria for all glazing used in federal buildings, which was later on adopted by the Interagency Security Committee (ISC) to broaden its use. Part of its approach is to quantify glass failure not in terms of whether breakage occurs, but rather the hazard it causes to occupants. Today, the ISC Security Design Criteria Blast Protection Levels for Windows is the most widely recognized classification of design levels for glazing hazard protection:

|

Performance Condition |

Protection Level |

Hazard Level |

Description of Window Glazing Response |

|

1 |

Safe |

None |

Glazing does not break. No visible damage to glazing or frame. |

|

2 |

Very High |

None |

Glazing cracks but is retained by the frame. Dusting or very small fragments near the sill or floor acceptable. |

|

3a |

High |

Very Low |

Glazing cracks. Fragments enter space and land on floor no further than 3.3 ft. from the window. |

|

3b |

High |

Low |

Glazing cracks. Fragments enter space and land on floor no further than 10 ft. from the window. |

|

4 |

Medium |

Medium |

Glazing cracks. Fragments enter space and land on floor and impact a vertical witness panel at a distance of no more than 10 ft. from the window at a height no greater than 2 ft. above the floor. |

|

5 |

Low |

High |

Glazing cracks and window system fails catastrophically. Fragments enter space and land on floor and impact a vertical witness panel at a distance of no more than 10 ft. from the window at a height greater than 2 ft. above the floor. |

But what happens when the same blast rated glazing system must also meet 2-hour fire resistive requirements, as well as deliver maximum transparency and seamlessly blend with the existing non-rated systems?

Such was the case with a public safety facility located in the east coast of the United States. The glass wall between the secure entrance and main lobby had to meet both ASTM E-119/NFPA 251 for 2 hours with hose stream as well as Performance Condition 2 of the ISC Security Design Criteria Blast Protection Levels for Windows. Additionally, the assembly had to meet the requirements in UFC 3-340-02, Structures to Resist the Effects of Accidental Explosions, UFC 4-020-01, Department of Defense Security Engineering Facilities Planning Manual and UFC 4-010-01, Department of Defense Minimum Anti-Terrorism Standards for Buildings. There was also an adjacent glass wall by the security officer’s desk that had to meet ASTM E-119/NFPA 251 for 2 hours and UL 752 Level 4 Ballistic.

Given the strict requirements of this project, SAFTI FIRST submitted a certified blast engineering report to the building team for the fire resistive, blast rated system, as well as provide a visual mock-up of the assembly. To achieve the level of fire and blast resistance needed, SAFTI FIRST provided SuperLite II-XL 120 with Heat Strengthened Laminated Glass that met the Performance 2 criteria. It was supplied with the GPX Blast Framing System with a custom designed anchoring system. SAFTI FIRST worked with the design team and blast consultant to ensure that the entire assembly worked with the surrounding structure to meet the required blast performance.

For the fire and ballistic rated system, SAFTI FIRST provided SuperLite II-XL 120 with Level 4 Ballistic Glazing. Some of these panels included an obscure spandrel for areas that needed additional privacy. It was supplied with the GPX Ballistic Framing System to ensure that the entire assembly was compliant.

Since maximum transparency and vision were important design requirements, all the SuperLite II-XL fire resistive blast and fire resistive ballistic glazed assemblies utilized Starphire Low-Iron glass for an ultra-clear appearance despite the robust glass make-up. The GPX Blast and GPX Ballistic Framing systems matched the clean, sharp sightlines and finish of the non-rated systems for a uniform look. Both framing systems were supplied pre-welded and pre-assembled in sections for ease of installation.

The building also benefited from SuperLite II-XL 120’s large clear view areas, with individual panels just under 4,876 sq. inches, which is SuperLite II-XL 120’s maximum clear view area and the largest available at that time (SAFTI FIRST’s SuperLite II-XLB product currently has a largest clear view area at 7,980 square inches).

SAFTI FIRST also provided the large, 10-foot, 90 minute fire resistive pair doors in the glazed assembly. They were supplied with custom hardware that was compatible with the specified card reader to ensure secure access to the building.

The result is a beautiful and elegant glass wall and entrance system that greets building occupants as they enter and leave the facility during work hours, and would protect them from fire, blast or ballistic threats should it occur.

References:

Eve Hinman, P.E. “Blast Safety of the Building Envelope,” Whole Building Design Guide, (October 19, 2011).

Joseph L. Smith, P.S.P. and Nancy A. Renfroe, P.S.P., “Glazing Hazard Mitigation,” Whole Building Design Guide (July 23, 2010).

Related Stories

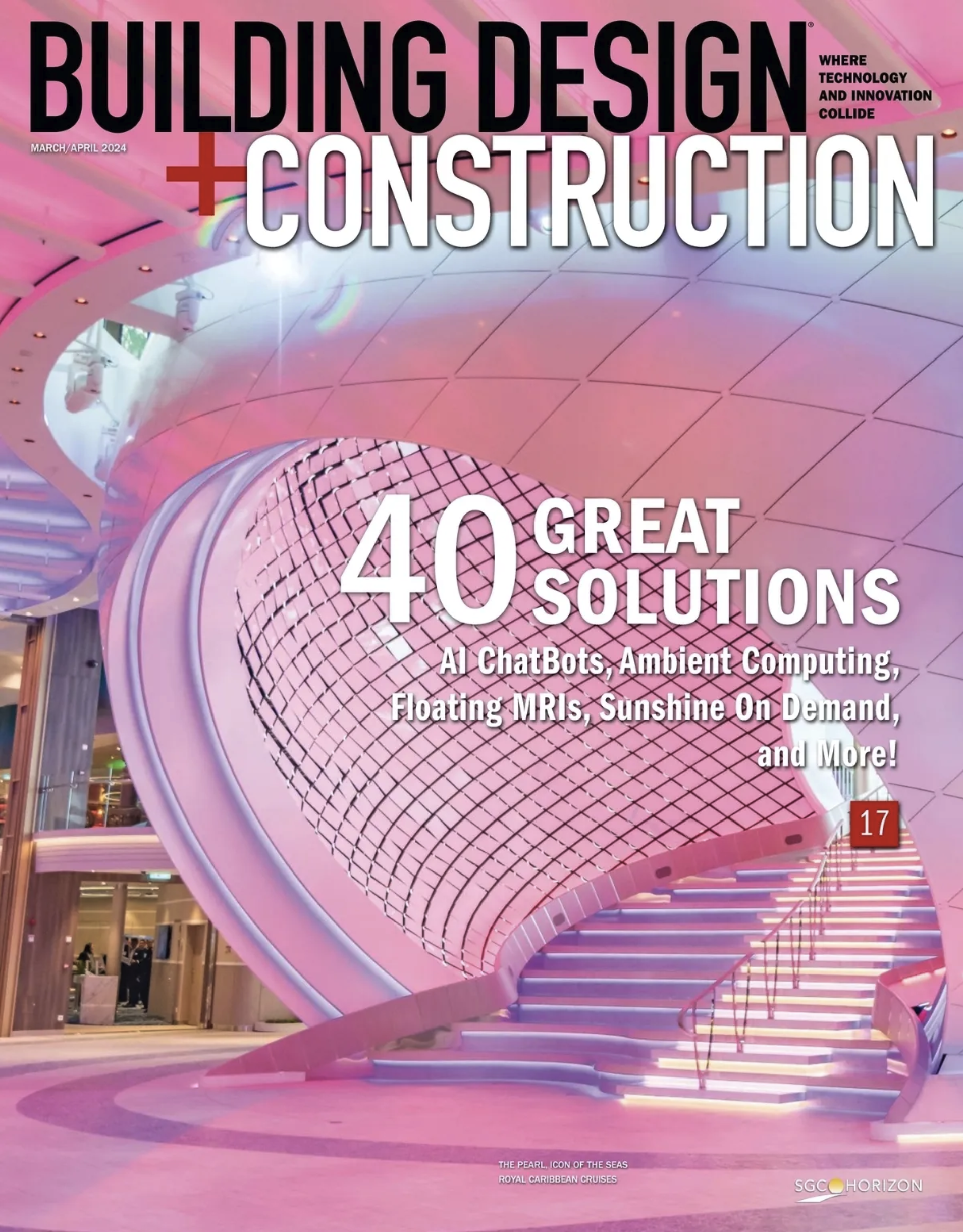

Fire-Rated Products | Apr 16, 2024

SAFTI FIRST launches redesigned website

SAFTI FIRST, leading USA-manufacturer of advanced fire rated glass and framing systems, is pleased to announce the launch of its newly redesigned website, safeglassforschools.com.

Products and Materials | Feb 29, 2024

Top building products for February 2024

BD+C Editors break down February's top 15 building products, from custom-engineered glass bridges to washroom accessories.

Products and Materials | Jan 31, 2024

Top building products for January 2024

BD+C Editors break down January's top 15 building products, from SloanStone Quartz Molded Sinks to InvisiWrap SA housewrap.

75 Top Building Products | Dec 13, 2023

75 top building products for 2023

From a bladeless rooftop wind energy system, to a troffer light fixture with built-in continuous visible light disinfection, innovation is plentiful in Building Design+Construction's annual 75 Top Products report.

Sponsored | MFPRO+ Course | Oct 30, 2023

For the Multifamily Sector, Product Innovations Boost Design and Construction Success

This course covers emerging trends in exterior design and products/systems selection in the low- and mid-rise market-rate and luxury multifamily rental market. Topics include facade design, cladding material trends, fenestration trends/innovations, indoor/outdoor connection, and rooftop spaces.

Products and Materials | Aug 31, 2023

Top building products for August 2023

BD+C Editors break down 15 of the top building products this month, from frameless windscreens to smart fixture mount sensors.

Glass and Glazing | Aug 25, 2023

Vitro Architectural Glass Lowers Embodied Carbon Further, Releases NEW Environmental Product Declarations

Vitro Architectural Glass (formerly PPG Glass) has published updated versions of its Environmental Product Declarations (EPDs) for both flat and processed glass. These updates reaffirm that Vitro’s glass products contain less embodied carbon than the industry standard for architectural glass products and indicate a lower embodied carbon value than previously reported in 2017 editions of these EPDs.

Fire-Rated Products | Aug 14, 2023

Free download: Fire-rated glazing 101 technical guide from the National Glass Association

The National Glass Association (NGA) is pleased to announce the publication of a new technical resource, Fire-Rated Glazing 101. This five-page document addresses how to incorporate fire-rated glazing systems in a manner that not only provides protection to building occupants from fire, but also considers other design goals, such as daylight, privacy and security.

75 Top Building Products | Aug 7, 2023

Enter today! BD+C's 75 Top Building Products for 2023

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2023 issue of Building Design+Construction.

Building Materials | Jun 14, 2023

Construction input prices fall 0.6% in May 2023

Construction input prices fell 0.6% in May compared to the previous month, according to an Associated Builders and Contractors analysis of the U.S. Bureau of Labor Statistics’ Producer Price Index data released today. Nonresidential construction input prices declined 0.5% for the month.