Since my 2013 blog post on our CLT visitor building at the Oregon Zoo, the amount of available reading material on CLT has increased dramatically. One topic remains difficult to track, yet seems to be the most critical of the moment: cost.

The zoo building opened in April, and as my involvement with conceptual exercises and real projects using this compelling material has continued, I’ve watched the question of cost, and cost estimating, become critical to solve. With the installation of our first project behind us, I thought I would be in a better position to find some answers.

There are long-term value considerations worth mentioning, like life-cycle value, embodied energy, and ease of retrofit, but the issues that really stop a cost conversation in its tracks are up-front, capital factors: material and labor costs, system assumptions, and procurement.

Image: SRG

Image: SRG

This past January, while on site at the zoo, I could actually stand in one spot, watch the CLT fly into place, turn around, and watch a similarly-sized standard Doug fir roof deck install on an elephant habitat shade structure. Could we compare the material and labor costs for the two structures? The contractor, Andy Dykeman at Lease Crutcher Lewis, mulled it over with me and the structural engineer, Ed Quesenberry with Equilibrium Engineers.

The CLT deck took less than half the man-hours to install than the shade structure deck. We all agreed that a subsequent job could count on greater labor efficiency, closer to one third that of the conventional system. In real time, the difference is even more striking. The CLT roof came together in one dramatic day, while it took two full weeks to install the Doug fir planks. That is a compelling cost story, more so as the scale increases, say, for a college looking to find a way to compress construction so a building can open before school starts.

There are many anecdotal stories, strong evidence of huge time and labor savings, like the eight-story Bridport Tower in the UK going up in half the expected time, 12 versus 24 weeks. And the two story elementary school in West Virginia that took two weeks to erect, with only three people needed in the field. But anecdotes aren’t quantifiable, and the real data unavailable, so the search continues.

Material reduction is a significant but elusive area of estimating a CLT building. Wood weighs much less than steel and concrete, so smaller foundations and less expensive structural resisting systems can be assumed. But early cost estimates rely on conventional assumptions; a good CLT building does not. It is nearly impossible to cost-compare a conventional system with a novel one without developing and estimating two completely different designs. The "novel" design, to be cost-effective, would need to use the system to its best advantage. Our building penciled out during design because we were able to take out enough steel, which was necessary to support Doug fir tongue-and-groove decking planks, to balance the material cost premium of CLT. The material’s inherent strength even allowed us to increase our overhang depth.

When we ordered our panels, there was one manufacturing option in the region, in Vancouver B.C.

Image: SRG

Image: SRG

Now there is a local, Oregon company, DR Johnson Lumber, in Riddle, Ore., beginning to produce CLT, which is encouraging for so many reasons. A fair procurement process with multiple bidders is important to ensure a balanced market and keep costs reasonable. Of course, it is also wonderful to be able to prioritize local businesses in our specifications when it makes sense.

While hard data about the cost of building with CLT remains just out of reach, it will take a combination of visionary clients, designers, and contractors to bring more significant CLT buildings to fruition in Oregon. It will take several of these projects to start to build a body of data that allows general assumptions to be made. I am convinced that these first teams will create success stories that the entire industry can build upon.

About the Author: Emily Dawson, AIA, joined SRG in 2007 driven to create enduring and meaningful public spaces. An architect with over 12 years experience on a range of public and higher education projects, her passion for connecting all players produces strong and inspiring projects. Dawson's commitment to sustainability permeates every planning and building project she engages, as does her sensitivity to form and beauty as crucial components of lasting work.

More from Author

SRG Partnership | Mar 6, 2023

Benefitting kids through human-centric high school design

Ingrid Krueger, AIA, LEED AP, shares why empathetic, well-designed spaces are critical in high schools.

SRG Partnership | Aug 10, 2022

Increasing the skilled workforce through career technical education

There is a shortage of skilled workers in the United States, a gap that has only gotten wider with the advent of COVID.

SRG Partnership | Aug 8, 2022

Mass timber and net zero design for higher education and lab buildings

When sourced from sustainably managed forests, the use of wood as a replacement for concrete and steel on larger scale construction projects has myriad economic and environmental benefits that have been thoroughly outlined in everything from academic journals to the pages of Newsweek.

SRG Partnership | Jun 9, 2016

Designing for interdisciplinary communication in university buildings

Bringing people together remains the main objective when designing academic projects. SRG Design Principal Kent Duffy encourages interaction and discovery with a variety of approaches.

SRG Partnership | Apr 9, 2015

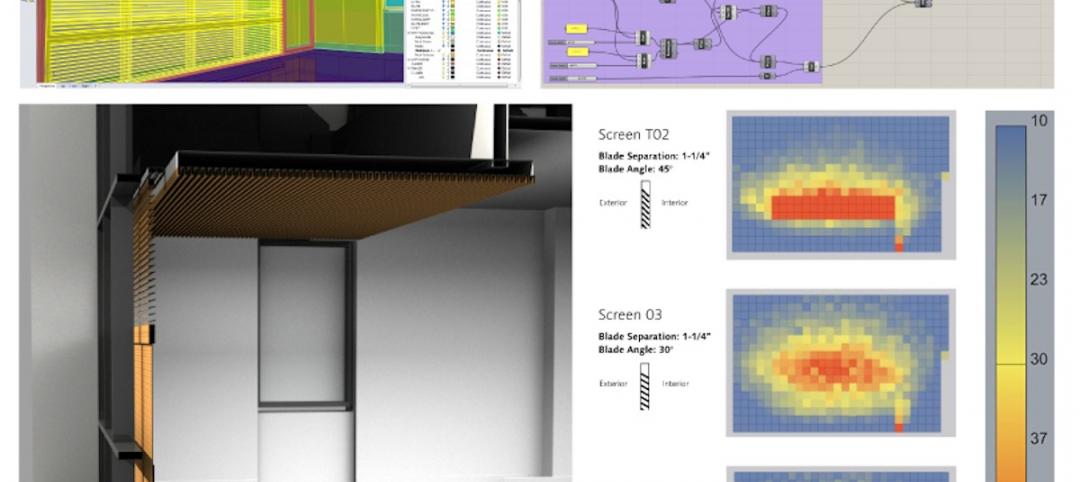

How one team solved a tricky daylighting problem with BIM/VDC tools, iterative design

SRG Partnership's Scott Mooney describes how Grasshopper, Diva, Rhino, and 3D printing were utilized to optimize a daylighting scheme at Oregon State University's new academic building.

SRG Partnership | Mar 23, 2015

Drones for AEC: How every stage of a building project can benefit from drone technology

From photo-mapping to aerial progress videos, SRG Partnership's Dmitriy Molla studies real-world applications for unmanned aerial vehicles.

SRG Partnership | Feb 9, 2015

The generalist architect vs. the specialist architect

The corporate world today quite often insists on hiring specialists, but the generalists have an intrinsic quality to adapt to new horizons or even cultural shifts in the market, writes SRG Partnership's Gary Harris.

SRG Partnership | Jan 5, 2015

Beyond training: How locker rooms are becoming more like living rooms

Despite having common elements—lockers for personal gear and high-quality sound systems—the real challenge when designing locker rooms is creating a space that reflects the attitude of the team, writes SRG Partnership's Aaron Pleskac.

SRG Partnership | Dec 18, 2014

In response to ultra-open and uber-collaborative office environments

Susan Cain’s bestselling 2012 book, "Quiet: The Power of Introverts in a World That Can’t Stop Talking" has made an impact on how we understand our current workforce, recognizing that at least one-third of the people we work with are introverts, writes SRG Partnership's Susan Gust.