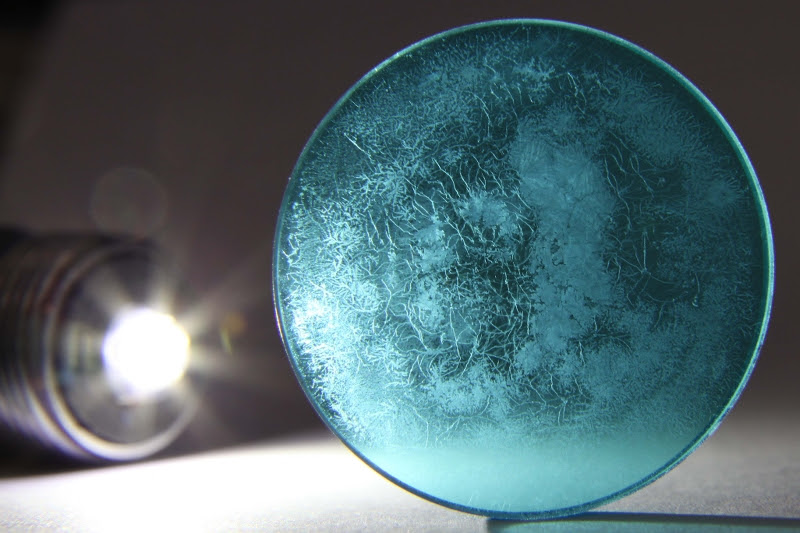

With all that’s been written about analytics, fault detection, automated diagnostics, and continuous commissioning, the truth is that the technology alone does not save money. It’s not about the technology - it’s about people, processes and implementation. Technology is merely the enabler. Analytics is a tool, not the remedy. Think of it this way - you don’t feel well so you go to the doctor and the doctor orders an MRI. The MRI costs money. However, the MRI does not cure your ailment; it simply gives the doctor insight as to what is wrong. The cure could be relatively simple (low cost) in the form of a prescription, or it could be major (high cost) in the form of surgery. Either of these remedies (corrective actions) will cost money in order to fix your ailment. The MRI is analytics; you need to spend money on it but by itself, it will not save you money.

Similar to the MRI, meaningful bottom-line results come from the implementation of recommendations identified by evaluating analytics. The change is a result of people and processes. While it’s true that you need good technology, technology is only an enabler of the solution; it is not the solution in itself.

Case in point, at a recent conference, there was a dizzying array of analytic products that shared similar features and all claimed to do the same thing. However, what seemed to be missing in all of the discussions was the importance of people and process in order to achieve a successful outcome. Further, there seemed to be a pervasive notion that analytics saves money. As stated, analytics can only provide insight into the actions necessary to save money.

The following are samples of key points that have little to do with technology, but are critical to a successful result.

Budget

How much money is allocated toward corrective action and preventative maintenance? This may seem obvious, but all the money spent on analytics won’t return a penny to the bottom line if the issues identified are not actually addressed. If an organization’s maintenance strategy is “run to failure,” it is virtually impossible for any analytics solution to achieve the desired results. The solution should be to identify and address the issue PRIOR TO failure. Sufficient money and resources must be allocated to correct the issues identified by the solution.

Process or Work Flow

Corrective action needs to be implemented in the context of a clearly defined process. The key to a successful strategy, one that is aligned with an organization’s budget and resources, is to build a process around the technology. The process manages the rate at which corrective action is taken to reflect that which the organization can effectively support. Identifying more issues than can be realistically addressed only serves to frustrate stakeholders and undermine support for the solution. The ultimate solution is built around a process that effectively triages, prioritizes, and ultimately, corrects the issues that have the greatest impact on the organization’s bottom line without placing an undue burden on its budget and resources.

We often hear that more data is better; more rules are better and so on. The truth is more is not always better if it does not align with the organization’s ability to process it, or return value sufficient to offset the cost to obtain it.

Prioritization and Cost Impact

There are a number of methods for prioritizing the issues identified by an analytics solution:

- Frequency – How many times did the fault occur?

- Duration – How long did the fault condition last?

- Cost impact – How much did the fault cost? Or, how much could the organization have saved if the fault was corrected? This is typically expressed in per hour units.

- Level of importance of the area served by the equipment associated with the fault.

Frequency and duration are easily understood and easy to quantify. However, cost impact is another story. There is very little quantifiable data available to measure cost impact; there are just too many variables that influence cost impact value. For example, consider an economizer failure. To have an accurate cost impact value requires consideration (at a minimum) of the following:

- Equipment age and condition

- Climate zone

- Hours of operation

- Energy cost

- Type of occupancy

For a single site implementation, this may not seem too difficult and would only need to be tailored for each asset to which this rule applies. However, when implementing this rule across hundreds of sites, the effort required to capture and input this data is a formidable task. As such, an approach that is effective in these situations is to apply some level of generalization. This provides a reasonable level of accuracy for the amount of time required to set up the data. Is it completely accurate for each piece of equipment? No. However, keep in mind that we are using this to prioritize corrective actions, not to predict absolute cost avoidance. Regardless of the method chosen, it should be something that is mutually accepted by the service provider and the customer. In this way, actions and results are transparent and understood by all stakeholders.

Corrective Action

Once prioritized, how are corrective actions implemented? Typically, they’ll fall into one of three buckets: immediate action, scheduled, or an aggregate. Immediate action items are those that are both urgent and important. Scheduled items are those that are important, but not necessarily urgent. And, other corrective actions can be aggregated together to form more strategic improvement projects. Regardless of the approach, it is imperative that the corrective action process keep pace with the issues that are identified.

Think of the process as a lens. In its initial deployment, we expect to find many issues. The rules provide a broad view of the portfolio, buildings, and assets. As issues are identified, prioritized, and corrected focus becomes more concentrated. Simply put, focus moves from the low hanging fruit to searching for “change in the couch”. If the process fails to correct the obvious, the change in the couch will never be found and efforts will be stymied. This is one of the primary purposes of the process; to “throttle” the amount of issues to a level that is consistent with that which the organization can handle from a staffing and/or budget availability standpoint.

The budget must provide for both the analytics solution and corrective action. It is rather straightforward to establish a budget for implementing the analytics solution. However, consideration must also be given to budgeting for continuous corrective action and the level of “throttling” that needs to take place to make the overall process sustainable. Identifying more than can be corrected is of little value and could ultimately be counter-productive to the effort.

Current Condition

What is the current condition of the equipment and is there an active program for maintenance and improvements? Once the analytics solution is run, what is it likely to find? A building or portfolio of buildings whose equipment is well maintained and has a regular replacement cycle in place will likely result in fewer “major” issues discovered by the analytics solution.

However, applying analytics to equipment that has not been properly maintained will likely result in significant findings that will likely include major repairs. This needs to be considered when planning an analytics solution because the findings could be overwhelming. This is not to say that it shouldn’t be done or that equipment that has not been maintained properly is not a good candidate for an analytics solution. Quite the contrary, these are excellent situations for analytics and the opportunity for meaningful results is significant. However, there needs to be a clear understanding that the problem wasn’t created overnight and it won’t be corrected overnight.

Conclusion

Implementing analytics should be done with the understanding that analytics alone is not a discrete project. Rather, it is a continuous process where issues are identified and corrected in a prioritized manner, within the limits of staff and budget. When those tasks are completed, another level of issues are identified and addressed. As each successive layer of issues is resolved, the process narrows its focus and moves to greater levels of detail, which continue to drive greater levels of efficiency and ultimately cost savings. Keep in mind, there is no “silver bullet” to achieve success. It’s an on-going commitment to continuous improvement.

About the Author: Paul Oswald joined CBRE in 2015 as part of CBRE’s acquisition of Environmental Systems, Inc. (ESI), a leading systems integrator and provider of energy management services. Now part of CBRE’s Global Energy & Sustainability (GES) services platform, Mr. Oswald is now the Managing Director of CBRE|ESI. Based in Brookfield, WI, CBRE|ESI assists CBRE clients with identifying and implementing portfolio-wide energy reductions, cost saving and sustainable operating practices within the broader GES service offering. Mr. Oswald leads a team of dedicated professionals and subject matter experts who provide services including strategy and design; system integration; turn-key project delivery; and managed services for HVAC, lighting, security, and energy; and control and metering systems. Mr. Oswald has over 35 years of experience in building automation, system integration and energy management. His experience includes product strategy and development, business and channel development, and service delivery. Prior to acquiring ESI in 2002, he worked at Tridium, Square D, and Invensys (now part of Schneider Electric).

Related Stories

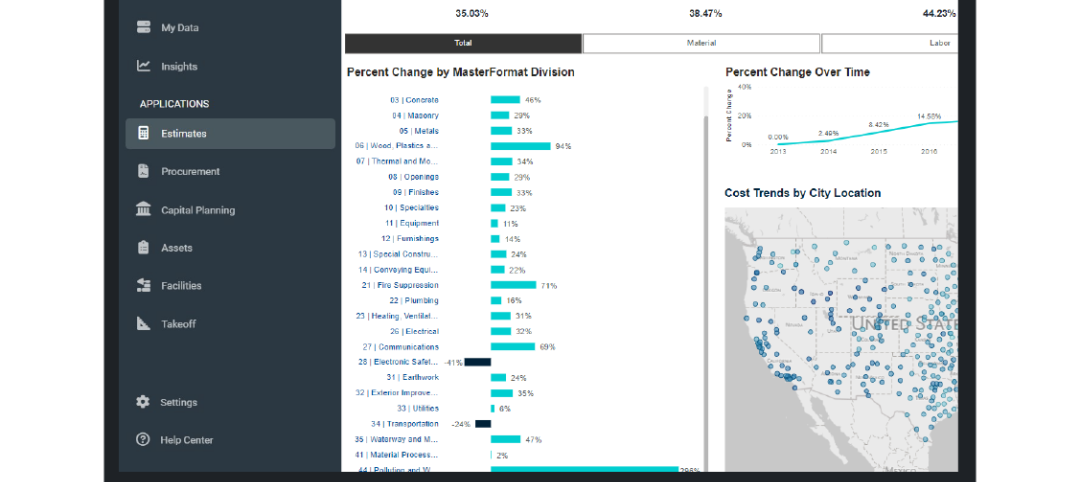

Sponsored | Big Data | Apr 17, 2024

A New, Better Way to Keep Up With Construction Material Cost Changes

Turn data into intelligence and empower your organization with the latest in construction cost Data Insights.

AEC Tech | Mar 9, 2024

9 steps for implementing digital transformation in your AEC business

Regardless of a businesses size and type, digital solutions like workflow automation software, AI-based analytics, and integrations can significantly enhance efficiency, productivity, and competitiveness.

AEC Tech | Feb 28, 2024

How to harness LIDAR and BIM technology for precise building data, equipment needs

By following the Scan to Point Cloud + Point Cloud to BIM process, organizations can leverage the power of LIDAR and BIM technology at the same time. This optimizes the documentation of existing building conditions, functions, and equipment needs as a current condition and as a starting point for future physical plant expansion projects.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

AEC Tech | Jan 24, 2024

4 ways AEC firms can benefit from digital transformation

While going digital might seem like a playground solely for industry giants, the truth is that any company can benefit from the power of technology.

Digital Twin | Jul 31, 2023

Creating the foundation for a Digital Twin

Aligning the BIM model with the owner’s asset management system is the crucial first step in creating a Digital Twin. By following these guidelines, organizations can harness the power of Digital Twins to optimize facility management, maintenance planning, and decision-making throughout the building’s lifecycle.

Digital Twin | Jul 17, 2023

Unlocking the power of digital twins: Maximizing success with OKRs

To effectively capitalize on digital twin technology, owners can align their efforts using objectives and key results (OKRs).

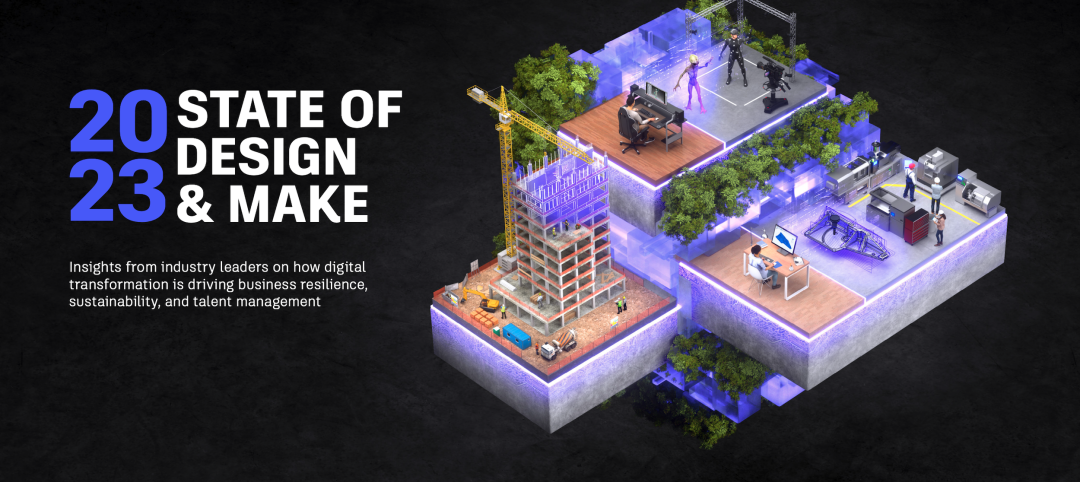

Sustainability | May 1, 2023

Increased focus on sustainability is good for business and attracting employees

A recent study, 2023 State of Design & Make by software developer Autodesk, contains some interesting takeaways for the design and construction industry. Respondents to a survey of industry leaders from the architecture, engineering, construction, product design, manufacturing, and entertainment spheres strongly support the idea that improving their organization’s sustainability practices is good for business.

AEC Tech Innovation | Apr 27, 2023

Does your firm use ChatGPT?

Is your firm having success utilizing ChatGPT (or other AI chat tools) on your building projects or as part of your business operations? If so, we want to hear from you.

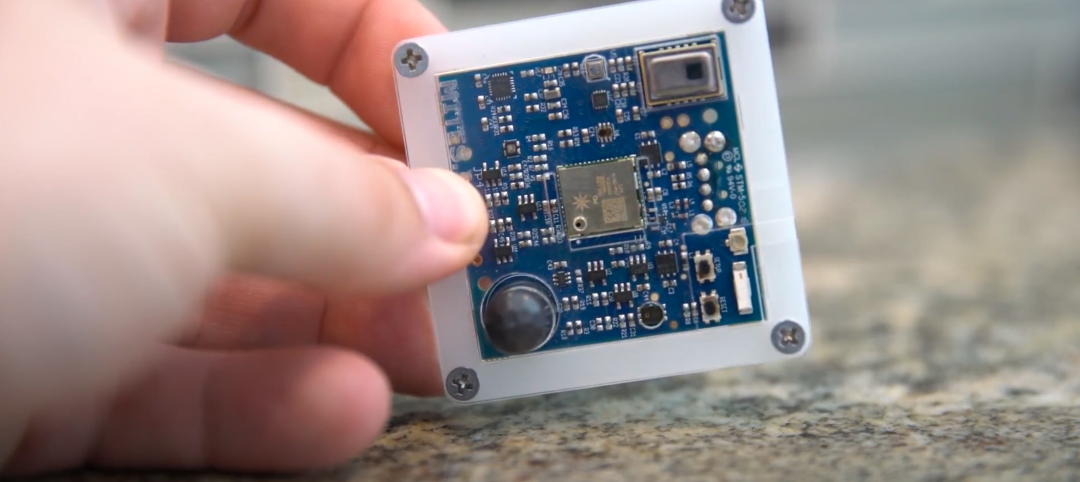

Smart Buildings | Apr 7, 2023

Carnegie Mellon University's research on advanced building sensors provokes heated controversy

A research project to test next-generation building sensors at Carnegie Mellon University provoked intense debate over the privacy implications of widespread deployment of the devices in a new 90,000-sf building. The light-switch-size devices, capable of measuring 12 types of data including motion and sound, were mounted in more than 300 locations throughout the building.